__________________________________________________________TISTAM____

ANTI CREEPING SEAL.

The AC – SEAL Floating Seal Device is a customized solute- on for rotating shafts with excessive radial movement it use in Centrifuges ,Separators, Rotating air compressors, Mixer , Agitators, Rotary transmissions Rotating Pumps. The temperature range for AC – SEAL is from – 90°C up to 250°C. for temperatures above 200 °C.

Standard material: Fluoroelastomer.

AC - SEAL Standard.

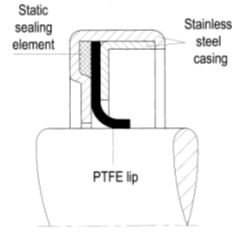

The seal is composed of a CREEPING seal lip with a static Vinton electrometric ring clamped in a stainless steel case.

The AC - SEAL standard is designed for a maximum pressure of 10 bar.

Typical applications:

(Centrifuges - Separators - Rotating air compressors – Mixer – Agitators - Rotary transmissions - Rotating Pumps)

AC - SEAL advantages: Maximum sealing surface speed to 45m/sec, Excellent chemical resistance, Low friction loss and wear resistant, Applicable in pressure and vacuum, Temperature to 250 °C and Good dry running capability.

Shaft hardness:

- Up to 1.5 bar min 45HRC.

- Above to 1.5 bar min 60HRC.

Pressure / Vacuum:

- AC – Seal standard : MAX 10 bar.

- AC – Lip : MAX 25 bar.

- AC – Special : MAX 25 bar.

AC – SEAL special types:

For engineering assistance please contact TISTAM to obtain an application data sheet.

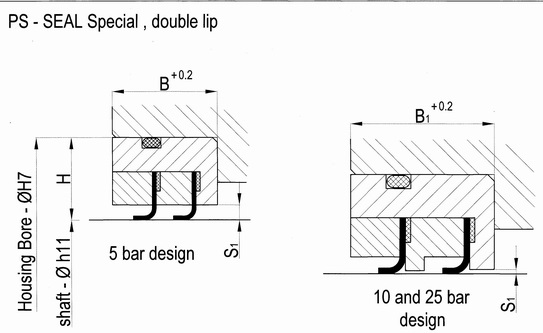

TISTAM® AC - SEAL Special, double Ordering example for shaft - ∅ 100mm and Pressure / vacuum;

TISTAM AC - SEAL Special, double lip,100x 130x17; 10bar with O-ring

AC – Lip SEAL:

The AC SEAL lip set includes a CREEPING lip element plus a Vinton static sealing element. AC – SEAL lips are available in any accordance with the AC -SEAL lip engineering data listing. AC – SEAL lips are widely used when a size does not fit our AC – SEAL standard size rang and where pressures above 10 bar are encountered.

Installation instructions:

The lip of AC – SEAL has to be mounted with care.

Prevention of damage is ensured by preparing the shaft as outlined.

If the AC – SEAL is assembled in the reversed manner it is recommended that a fitting cone is used, The surface of the cone and of the shaft should be polished and free from scoring.

.jpg)