__________________________________________________________TISTAM____

TISTAM® provide different types of a rotary joint depend on mechanism used to transfer liquids and/or gases while rotating / swiveling from one connection to another. Rotary unions are engineered to endure a large range of temperature and pressure for a variety of conditions and environments. In addition, rotary unions may integrate multi plepassages and handle different types of media concurrently.

Rotary unions function by connecting to an input and securing onto another mechanism while allowing a moving connection to be preserved. They are utilized in a variety of applications; from miniature rotary unions for the semiconductor industry to large, heavy-duty rotary unions for industrial applications. Additionally, numerous materials, seals, and bearing types can be incorporated.

__________________________________________________________TISTAM____

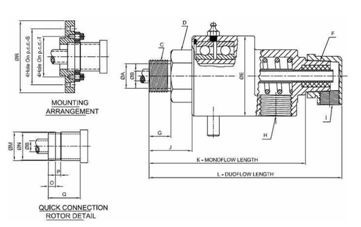

Double ball bearings:

balanced face sealing. lapped to optical, flatness, secondary sealing of Nitrite / Viton / PTFE. Available in MONO FLOW, DUO FLOW with fixed siphon and rotating siphon.

Max - RPM 1500 Max: Pr. 35 Kg/cm2 .

Max - temperature 100 °C Media-Water.

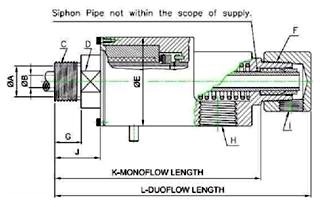

Rotor resting between one ball bearing and carbon graphite:

Bush bearing enabling thermal expansion. Balanced face seal lapped to optical flatness, available in MONO FLOW. DUO FLOW with fixed siphon and rotating siphon.

Max.-RPM 1500 Max:Pr.17Kg/CM2

Max temperature 160 °C

Media- Water, Steam and Thermal Fluid.

Rotary Pressure Joint:

with best quality carbon graphite guide bush and sealing ring, Rotor one piece carbon steel Available in MONO FLOW, DUO FLOW with fixed siphon or rotating siphon.

Max - RPM 600 Max Pr.17 Kg/cm2.

Max – to 350 °C Media- steam.

High Temperature:

Rotor and Outer body made of temperature resisting Steels. Optically flat lapped Tungsten Carbide seals are held by 99.99% pure graphite bushing to withstand very high temperature of Thermal Fluids.

Max RPM: 250.

Max Temp.: 350° C.

Max Pr. 5 kg/cm2.

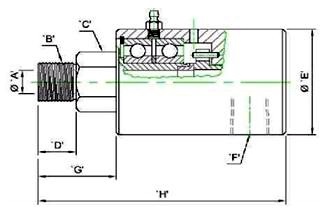

Rotor resting between two ball bearing:

Ensuring long life to sealing faces which are micro-lapped to optical flatness.

Max RPM 3500.

Media- Air and Hydraulic seNice.

Max;Pr. Air 10 Kg/cm2 Hydraulic 35 Kg/cm2.

Carbon seals for steam head seals.

(Steam header seals)

The steam header seal, or in more general terms the feeder head seal, represents a special from of Mechanical seal.

Usually the running speed with values of <0.1m/sec The load however can exceed 150 N/cm2 .

Spring load: 1-3 N/ cm2

__________________________________________________________TISTAM____