Pumps Service >> Pumps repair

____________________________________________________________TISTAM____

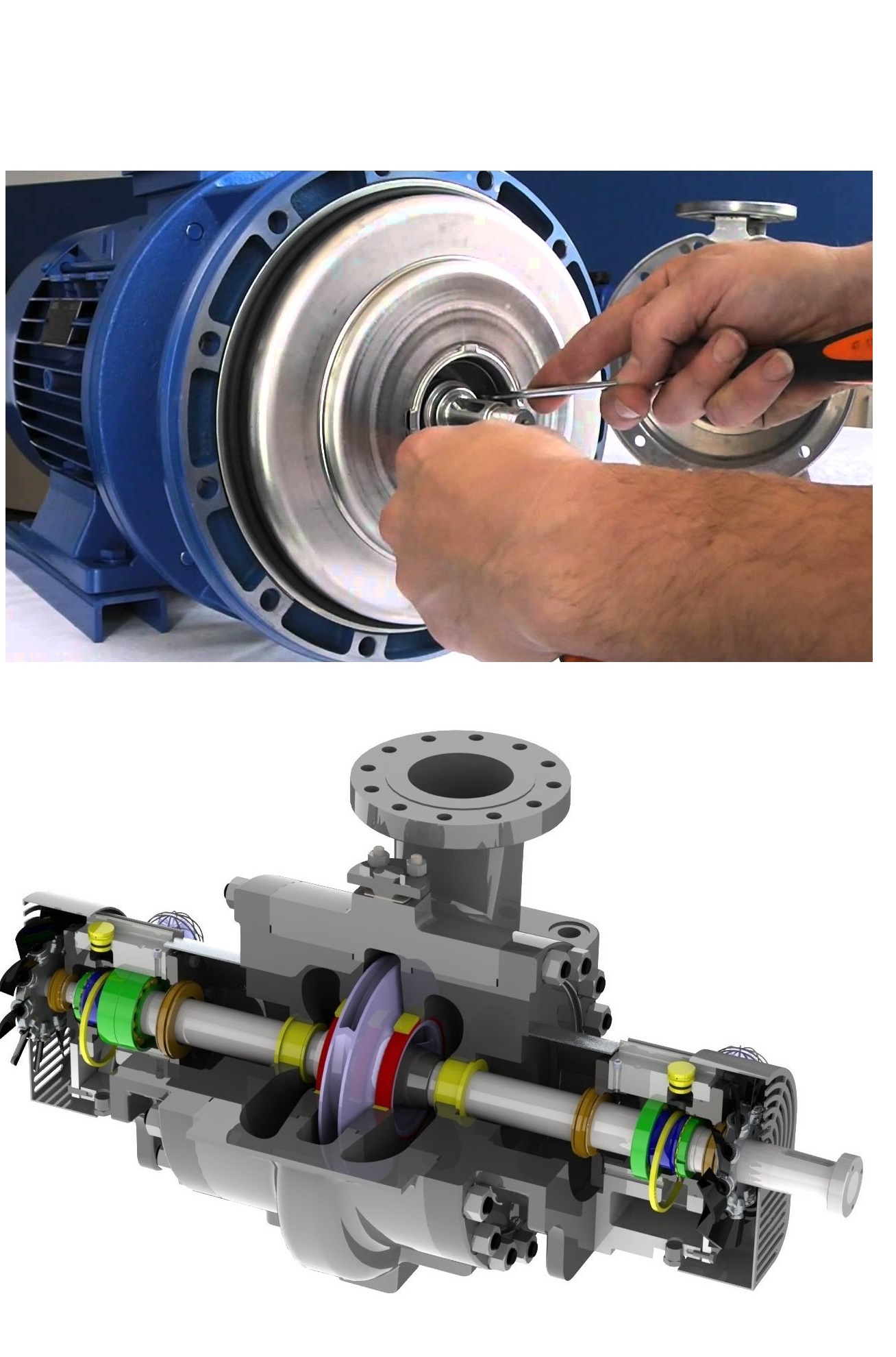

At TISTAM®, The first goal is to lower the operating costs and increase the bottom line profitability of our customers. By utilizing our pump repair capabilities and total systems approach, we help customers lower their total operating costs by optimizing the performance, reliability and service life of their pumping systems with engineered upgrades, improvements and results.

Our professional trained staff is knowledgeable about every aspect of the pumps & process equipment repair/rebuild business. With many years of hands-on experience, our technicians are the best in the field.

TISTAM mission is to provide customers with the proper information and the best pump repair service faster than anyone else in the business. This passion for quick .

TISTAM provide customers a factory trained resource for repairing their pumps and other fluid handling equipment, on call 24/7 for emergency service. Thats peace of mind.

Progress Pump & Machine Services provides dynamic balancing for all types Capable of field balancing, also in house Will balance per customer’s request Provide full guarantee for all parts repaired.

____________________________________________________________TISTAM____

TISTAM has a team of specialists who can advise you on virtually all issues relating to fluid transport, including highly demanding and critical applications. Thanks to special training and many years of collective experience, they have an in-depth understanding of the challenges you face. That means you can discuss the most complex pump issues with us, as well as the most effective way to address them.

Maintenance engineering provides you with the following benefits:

Higher yields.

Lower energy costs.

Optimum performance of your production process and pumps.

All our services are supported by our Maintenance Engineering & Consultancy department. That means TISTAM® is not just a specialized partner for matters relating to pumps, but takes an overall view of the role of pumps in your total process. This enables our specialists to optimize your process performance, leading to higher yields and lower costs.

We have a strict procedure that is followed by all our technicians which maximizes the speed and efficiency with which the pump can be stripped, inspected quoted and then repaired back to manufacturer standards.

Parts: Degasser Clamps, Shafts, Sleeves, Rings, and Nuts per customer specifications, Reverse engineer parts and manufacture samples.

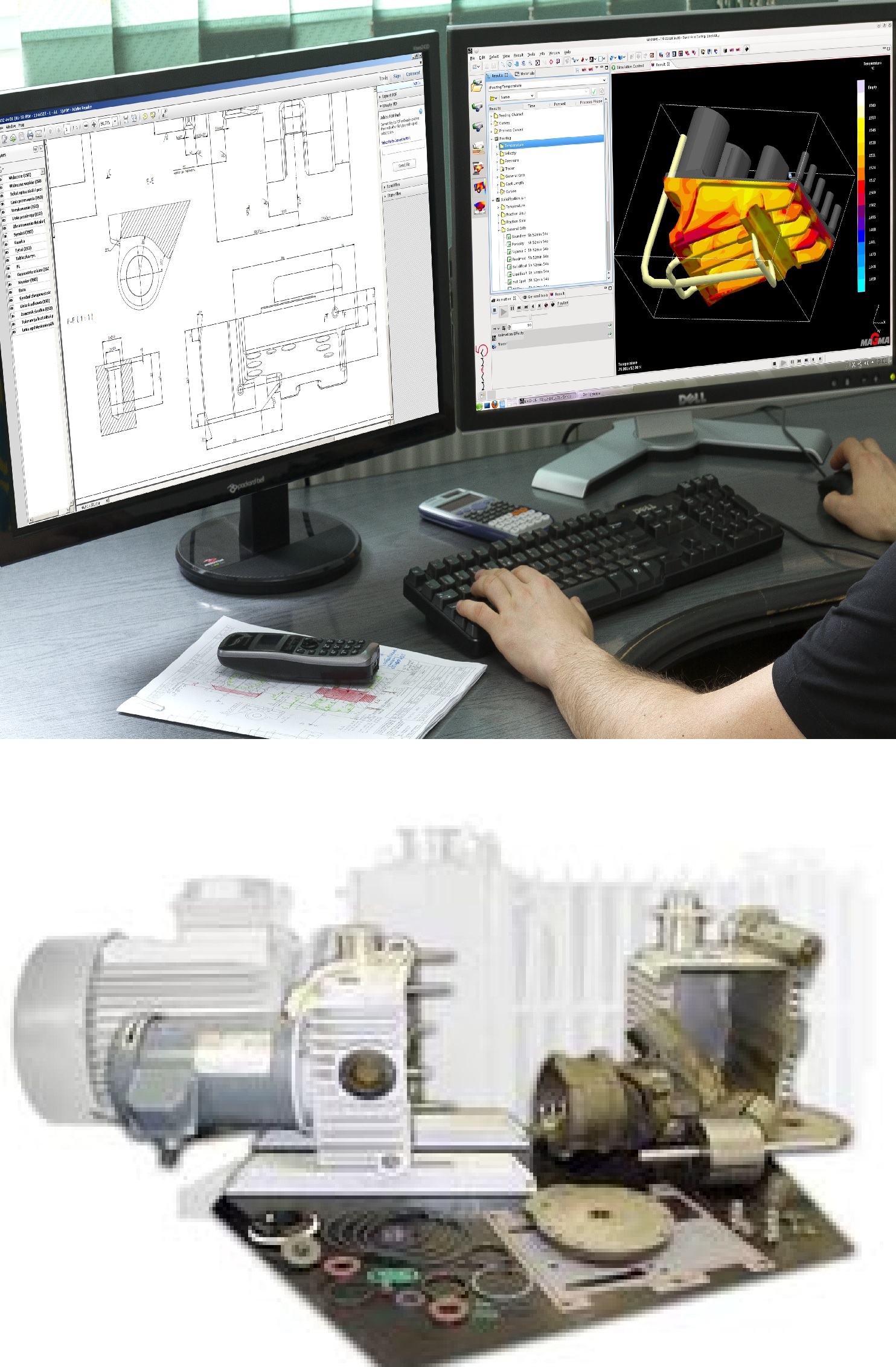

Drawings: Operational Computer Aided Design System (CAD)&(Solid work).

Engineering: Complete Component Engineering/Design; Reverse Engineering-Equipment Modification /Upgrade.

Trouble Shooting: System, Vibration and Failure Analysis; Component Repair Tracking Field machining Removal, Repair and Installation, Technical Support, Machining and Mechanical.

Welding: Specialty …SMAW (MMA), GMAW (MIG AND MAG), GTAW (TIG), on ferrous and non-ferrous metals New.

____________________________________________________________TISTAM____

•In-House or On-Site Pump Repairs / Rebuilds / Refurbishments.

•24 Hour Emergency Pump Repair Service - Pump & Equipment Pickup and Delivery Available.

•TISTAM provide all spare parts and accessories such as:

-Impeller, Volute or diffuser style casing, Shaft, Shaft sleeves, Bearing, Sealing arrangement,,etc.

•TISTAM provide different verities of Repair Kits for the following:

-All Pumps regardless of manufacturer.

-Valves - Gearbox Repair and No-Load Spin Testing.

-Blowers .

-Clarifier and Thickener Drives.

-Homogenizers.

-Pipe/Piping Systems- Steel, Teflon-Lined, Fiberglass, etc.

-Liquid Ring Compressors.

-Vacuum Pumps.

-Mechanical Pumps.

-Mechanical Seals.

-Mixers.

-Agitators.

____________________________________________________________TISTAM____

TISTAM® offers a comprehensive quality service for the maintenance and overhaul of pumps, both on location and in our workshops. We have 30 years of experience and are located close to the major industrial regions, which means we can respond quickly and effectively to your needs. Our point of departure is finding the optimal balance between the most economic solution and sustainability.

Our field services include:

Overhaul & Repair on location

Installations

Inspections

Start-up services

Vibration measurement

On-site balancing

Lubrication service

Laser alignment

Our in-house services include:

Overhaul & Repair

Dynamic balancing

Reconditioning; all spray, coating and machining works

Access to extensive test facilities

TISTAM has built excellent relationships with a wide range of pump suppliers thanks to its many years of experience in the pump industry. These close relationships enable us to supply your pump with original spare parts direct from the Original Equipment Manufacturers . As a result, we can service, repair and overhaul almost any brand of pump.

TISTAM assess the condition of your pump and take any necessary measures to reduce the risk of downtime.

TISTAM can plan maintenance more efficiently, so ensuring that your maintenance costs are manageable.

TISTAM prevent production downtime.

TISTAM achieve an optimum service life for your pump.

____________________________________________________________TISTAM____

Operation basics:

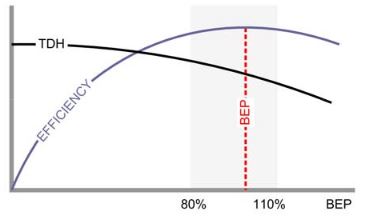

Best Efficiency Point(BEP), the flow rate where a pump has its highest efficiency, is a key factor to assess whether a pump is being operated properly. Few pumps operate at their exact BEP all of the time, because process variables in a production environment are not 100 percent constant. But a pump that is properly sized for its application will maintain a flow near peak efficiency. Maintaining a flow between 80 percent and 110 percentof BEP is a good range to maximize efficiency and minimize the risk of excessive wear or pump failure.

Pump monitoring and maintenance.

In the ideal world, all pumps would be properly sized to run constantly at their best efficiency points. In the real world of an industrial plant, this is impractical because processes are fluid both literally and figuratively.

Formulations change and productionrates vary, but typically the hundreds if not thousands of pumps supporting process do not change with them.The solution to maintaining reliable pump operations is a robust maintenance program that combines monitoring basic machine health data in addition to pump operating conditions.

There are four areas that should be incorporated in a pump maintenance program.

Pump performance monitoring and pump system analysis.

Vibration monitoring.

Bearing temperature.

Visual inspections.

Individually, each of these is importantindicators; collectively, they provide a complete picture as to the actual condition of the pump.